冷却过程作为数据中心内最要的空气处理过程,主要有机械制冷和自然冷却之分。

2024-03-30 01:18:14

456

动态新闻

Analysis of principle of air cooled precision air conditioning

The cooling process is the most important air processing process in the data center, mainly including mechanical cooling and natural cooling.For the mechanical refrigeration system, there are mainly direct expansion type and water cooling type. What is the difference between the two, and we will elaborate on it in the following article.Today, we mainly share the direct expansion precision air conditioning system, and the air cooling precision air conditioning unit in the direct expansion precision air conditioning system.

Straight expansion type air conditioning equipment

Straight expansion type (DX) is the abbreviation of direct expansion type, which is mainly used in systems with small cooling capacity.Straight expansion precision air conditioning itself is a combination of air conditioning system and refrigeration system, with heating, humidification, cooling device to treat the air.

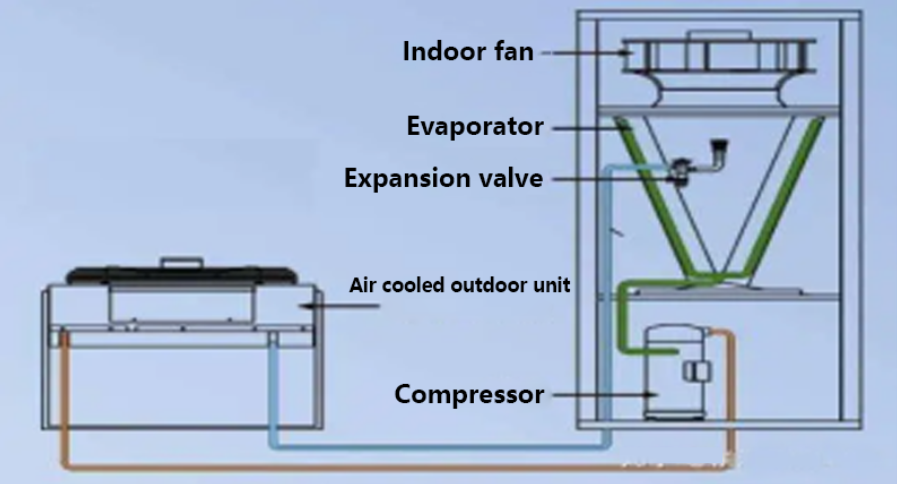

The direct expansion precision air conditioning is relatively independent, and the cooling system belongs to the distributed cooling system.The refrigeration system of air-cooled direct expansion precision air conditioning is composed of four parts: evaporator, compressor, condenser, throttle (expansion valve, capillary, etc.). The evaporator, compressor and throttle are generally arranged in the machine room, and the condenser is arranged outside.

The refrigeration system of air-cooled direct expansion precThe refrigerant is generally freon, and the single refrigeration capacity is 10-120KW.The unit draws heat from the room or cabinet and transmits it to the outdoor air through the condenser. High temperature and humidity control accuracy, smooth operation, convenient maintenance, suitable for areas with water shortage and places without cooling water system.

Air-cooled straight expansion air conditioning features

When the scale of the data center is small, air-cooled direct expansion precision air conditioning can be used. Its main characteristics include:

Direct evaporation and refrigeration cycle, no freezing water and cooling water system;

The installation of outdoor units is scattered, do not need to consider the bearing problem of outdoor units too much, but need to occupy a large amount of outdoor area;

If there are many outdoor units, multiple outdoor units are easy to form local heat island effect when installed too closely, insufficient heat dissipation causes outdoor units overheating and condensation pressure is too high;

Each set of air conditioning is relatively independent control and operation, easy to form redundancy, high reliability;

The installation and maintenance are relatively simple, and the construction cost is lower than that of large refrigeration systems;

Each unit is a refrigeration and air conditioning unit, the system structure is simple, does not need a complex operation control system;

Convenient to increase or decrease the number of equipment, conducive to local capacity expansion and phased construction;

The indoor and outdoor machines are connected through the refrigerant tube. The refrigerant tube should not be too long and should be controlled within 50cm.

Cooling principle of the air-cooling system

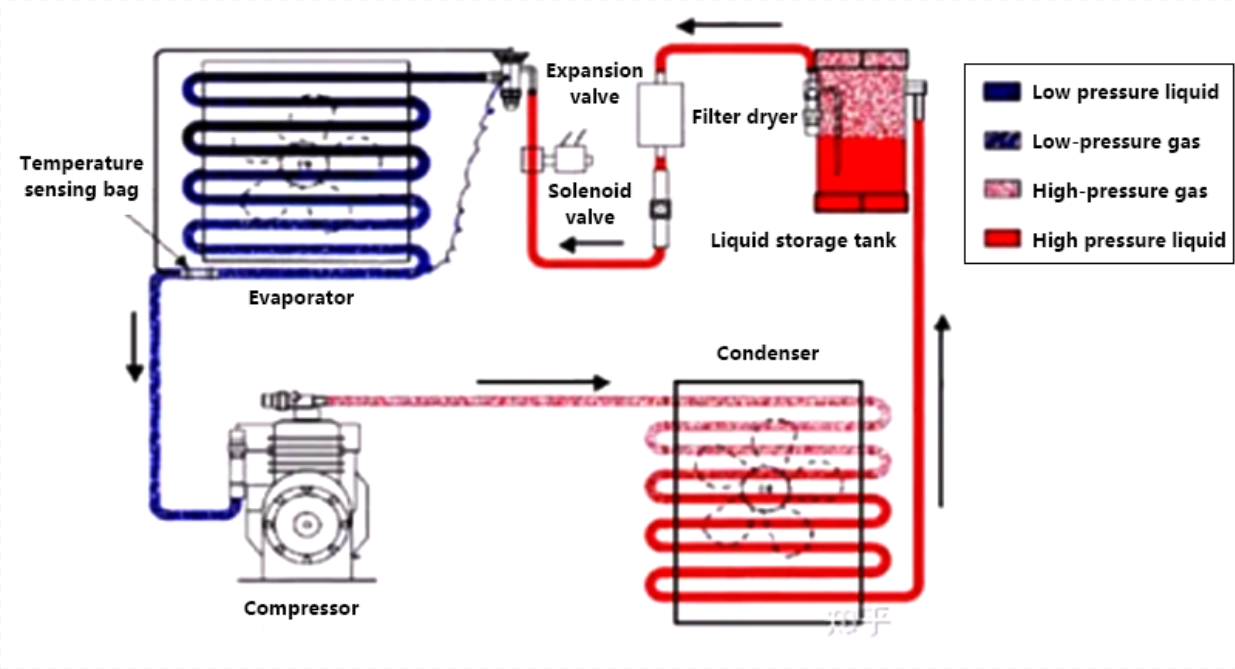

Air-cooled direct-expanded precision air conditioning is to cool the refrigerant in the condenser directly through the external air. The refrigeration process is performed as follows:

Low temperature and low pressure liquid refrigerant (Freon, etc.) vaporizes in the evaporator to absorb the indoor air heat;

The gaseous refrigerant is converted into high temperature and high pressure steam by the compressor, and is sent to the outdoor condenser;

High temperature and high pressure gaseous refrigerant is converted into low temperature and high pressure liquid refrigerant by condenser cooling (air cooled by air cooled and water cooled by water cooled);

The low temperature and high pressure liquid refrigerant is converted into a low temperature and low pressure liquid refrigerant after the throttling element, thus completing a refrigeration cycle.

Schematic diagram of air-cooled direct expansion precision air conditioner

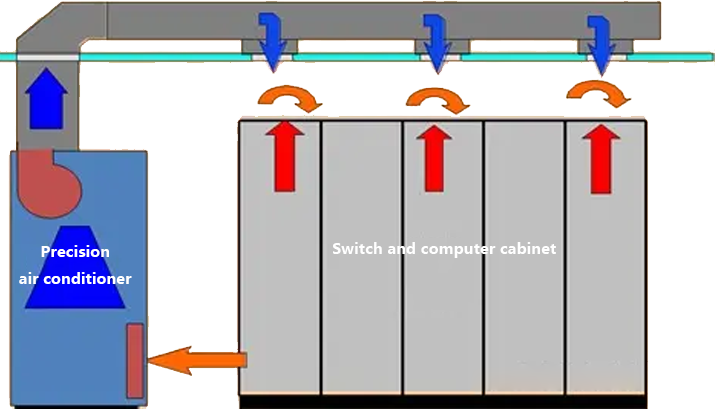

The air-cooled direct-expanded precision air conditioner is generally deployed on one side or both sides of the machine room. The air flow organization modes in the equipment room are generally adopted: air supply scheme on the air supply pipe and air supply scheme under the overhead floor.

The air supply mode on the air duct refers to that the air supply pipeline is laid over the machine room, and the cold air is sent out through the air supply louver opened under the air duct, and the negative pressure is returned to the air conditioner after the IT equipment warms up. The advantages of this method are the fast installation and the low construction cost.

Schematic diagram of air supply on the air duct of the machine room

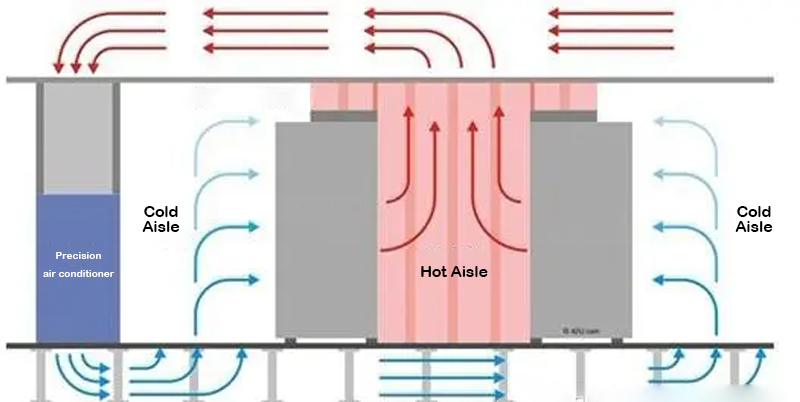

The disadvantage is that limited by various cable arrangement and building height, the section of the air supply pipe can not be enlarged, resulting in high wind speed and the air supply volume can not be adjusted flexibly. This air supply mode is more used in the low heat density machine room.Under-floor air supply is another reliable option. Even now, underfloor air supply is still used and built in a number of data center projects.

Schematic diagram of air supply under the floor of the machine room

This method uses the lower space of the overhead floor as the air supply static pressure box, which reduces the dynamic pressure of the air supply system, increases the static pressure and stabilizes the air flow. The air conditioner sends the cold air to the floor, through the air supply floor, and through the air inlet at the front end of the IT equipment. The advantage of this method is that the air supply volume at each point in the machine room can be adjusted by the opening rate of the air supply floor. At the same time, through the reasonable layout of cables and pipelines in the data center room, a small amount can be laid under the floor to ensure beauty. The disadvantage is that with the growth and adjustment of the use demand, the cable laid under the floor is increasing, resulting in poor air supply, and even the formation of fire hazards.