来自蒸发器的制冷剂蒸汽流入压缩机,经螺杆压缩机加压升温后排入油分离器,在高压气体流进冷凝器换热管束之前将油分离出来。冷凝器中的冷却水吸收制冷剂蒸汽的热量,使之冷却、冷凝。

2024-05-02 01:07:36

798

动态新闻

Screw type central air conditioning beginners: working principle and practical knowledge in a net

air conditioning chiller

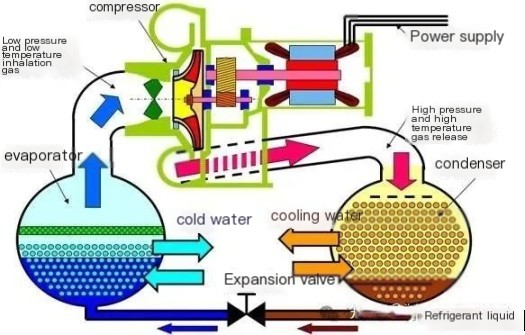

Air conditioning chiller iscomposed of host, terminaland peripheral equipment. The main engine is responsible for providing 7 degrees of cold water to the terminal equipment, and the terminal uses the cold water and filtration devices provided by the chiller to treat the air sent to the air-conditioned room to the appropriate temperature, humidity, cleanliness and fresh air ratio.

The peripheral equipment includes water pump and cooling tower, which is responsible for conveying chilled water and cooling water. Frozen water is cold water of 7 degrees. The cooling water takes away the heat generated during the cooling process of the system, and conducts heat cooling with air in the cooling tower, and then returns to the condenser.

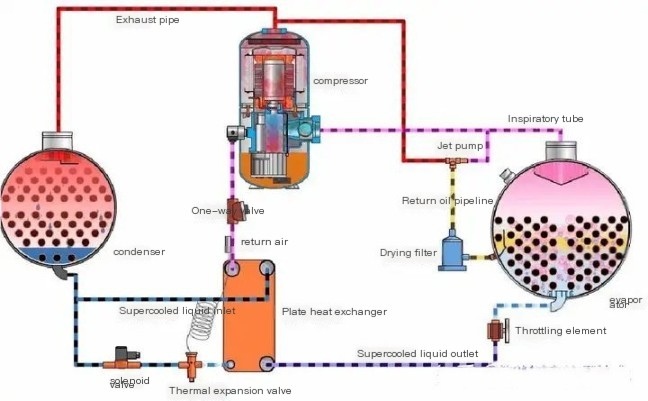

Working principle

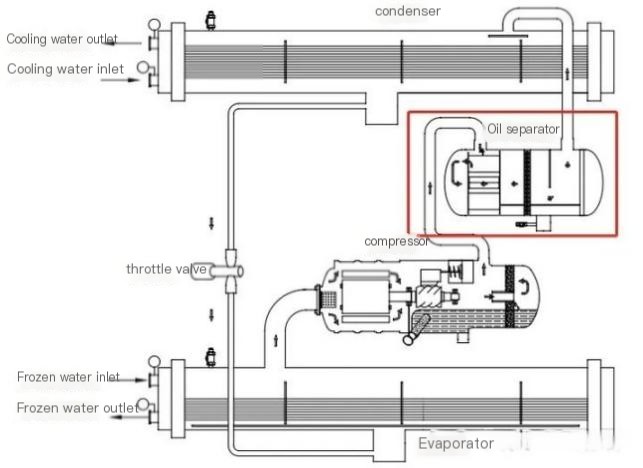

The refrigerant steam from the evaporator flows into the compressor through the screw compressor and discharged into the oil separator before the high pressure gas flows into the heat exchange bundle of the condenser. The cooling water in the condenser absorbs the heat of the refrigerant steam and makes it cool and condense. Cooling water is provided by external water sources, generally by cooling towers. After condensing, the refrigerant liquid enters the liquid pipe from the condenser, and the refrigerant supply of the evaporator is controlled by the throttle device inside (by the fixed hole plate and solenoid valve), thus completing the whole refrigerant cycle.

compression engine

The high-speed rotation of the low pressure cryogenic refrigerant of the evaporator requires the motor drive, the compressor and motor are separated with reliable seal and connection, the motor uses air cooling; the compressor is a double screw type compressor with volume type, direct start and double screw rotor. The motor directly drives the Yang rotor, and the Yin rotor depends on the Yang rotor to drive. The rotor and the rotor and the compressor housing do not contact each other, and the rotors are separated from each other by the pressure oil seal. The oil seal prevents high pressure gas leakage to the low pressure area.

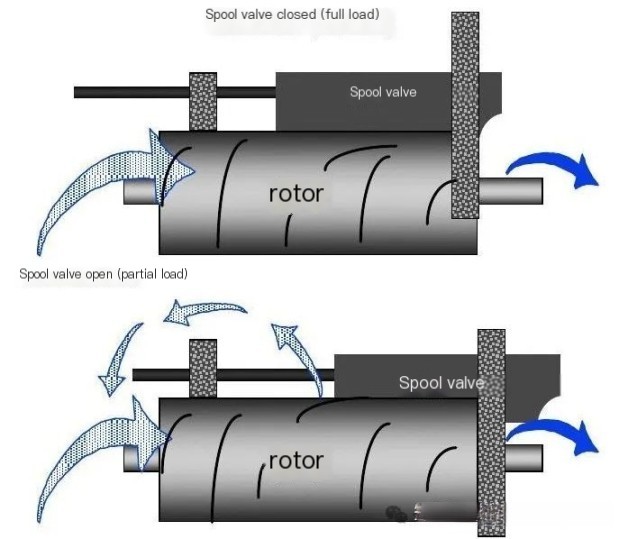

Sliding valve

The slide valve is used to stepless control the capacity (from 100% to 15% precision control). The slide valve is controlled by the microcontrol board through the oil pressure, and the part does not load when turned on after normal shutdown.slide valve: cooling control is achieved by pushing the slide valve with differential pressure.

Control: The slide valve adjusts the compressor exhaust volume to suit the system requirements by making an axial movement between the compressor and the screw. The sliding valve mechanism in the screw compressor adjusts the unit capacity according to various working conditions. The sliding valve mechanism is controlled by the control center and the control parts of the test condition. The control center sends a signal to the solenoid valve and uses the compressor lubricating oil to load or unload the slide valve. A spring pre-tightened shaft and piston (live valve) are placed in a slide valve cylinder at the end of the compressor. The slide valve is moved in the cavity by a high-pressure lubricating oil thrust. The lubricating oil at the high pressure end flows through the oil supply hole on the piston, and the flow of the lubricating oil is controlled by the equilibrium solenoid valve, which adjusts the loading or unloading of the slide valve, so as to increase or reduce the refrigerant flow into the compressor, and finally control the capacity of the unit.

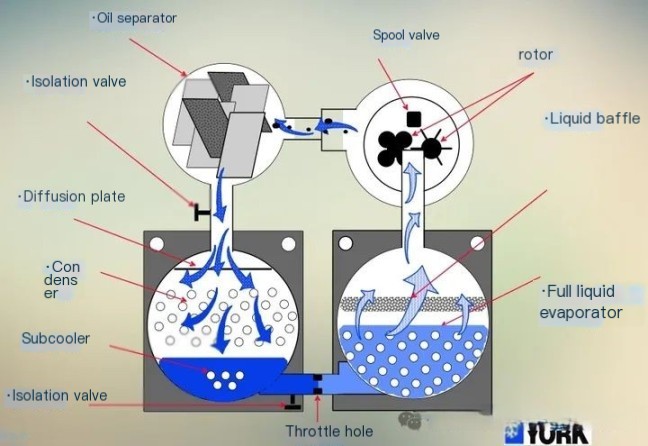

Oil separator

The oil separator injects the oil into the compressor by gravity and the filter screen to separate the steam \ oil before entering the condenser. Oil separation has 3 oil type. First stage separation: in the first stage of oil separation, the speed of the high-speed refrigerant and oil mixture just enters the large diameter oil content decreases quickly, and the vast majority of oil can be separated from the refrigerant airflow due to the reduced speed, and the separated oil falls in the oil tank located at the bottom of the oil separator due to the action of gravity.

Secondary separation: in the second stage of oil separation, the refrigerant gas passes directly through a filter screen with an expanded surface. Small oil droplets converge on the surface of the filter and then fall into the tank at the bottom of the oil separator.

Three stage separation: the third and final stage of oil separation is achieved through the coalescent cylinder of oil separation. The refrigerant and oil mixture entering the cylinder are smoke-like gas. These gas mixture weet the surface of the cylinder and collects at the bottom of the cylinder due to gravity. The oil gathered through the conduct is discharged from the oil separator through the catheter.

Oil level control of oil separator: The oil separator is equipped with 3 mirrors, through which the oil level condition can be observed and the operation of the coaler cylinder can be confirmed. When the chiller is shut down, the liquid oil can be seen from the highest lens; during the unit operation, the oil level may be high or low, as determined by the system load and actual working conditions. The oil separator is extremely efficient and separates almost 100% of the oil. A very small amount of oil from the oil fraction through a drying filter is returned to the compressor.

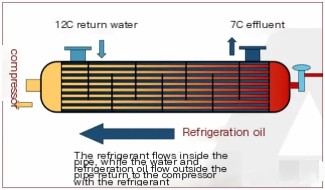

The refrigerant gas separating the oil enters the condenser from the oil separator. The cooling water of the condenser copper pipe takes away the evaporator heat load, presses the heat and condenses the refrigerant gas into the refrigerant liquid. The refrigerant liquid then flows through the supercooler at the bottom of the condenser, and the supercooled refrigerant liquid then flows into the evaporator through the differential pressure difference.

Evaporator

Function: Keep the frozen water at a constant low temperature by exchanging the refrigerant with the frozen water. The top of the evaporator is welded with a baffle, which can accumulate the oil falling from the compressor, which can prevent the oil from mixing with the refrigerant, and it can also prevent the refrigerant liquid strike phenomenon in the compressor.

The internal components are composed of: steam and liquid separation plate, distribution plate, hydrophotroscope, etc.

Steam-liquid separation plate: to prevent the liquid from entering the compressor;

Distribution plate: can make the refrigerant evenly distributed along the shell direction, so that the heat transfer effect is the best;

Lieroscope: easy to determine the refrigerant charge;

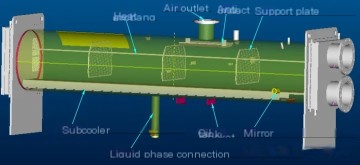

Condenser

Cooling water is used to condense the refrigerant steam and cooling the refrigerant into liquid into the evaporator

Internal components are mainly: exhaust baffle, overcooler and so on.

Exhaust baffle: prevent gas direct high-speed impact tube bundle, reasonable distribution of gas, so that the heat transfer effect is the best.

Overcooler: effectively superthe liquid and improve circulation efficiency.

the throttle plate will be the high temperature and high pressure liquid in the condenser into low temperature and low pressure liquid refrigerant into the evaporator.