风冷模块式冷热水机组的安装内容分为:主机安装、风机盘管安装、风管安装、辅助设备安装、水管施工、配电及通讯等。

2024-03-29 12:48:52

392

动态新闻

Installation content of air cooling modular cooling and hot water unit

The installation contents of air cooling modular cooling and hot water unit are divided into: host installation, fan coil installation, air duct installation, auxiliary equipment installation, water pipe construction, power distribution and communication, etc.

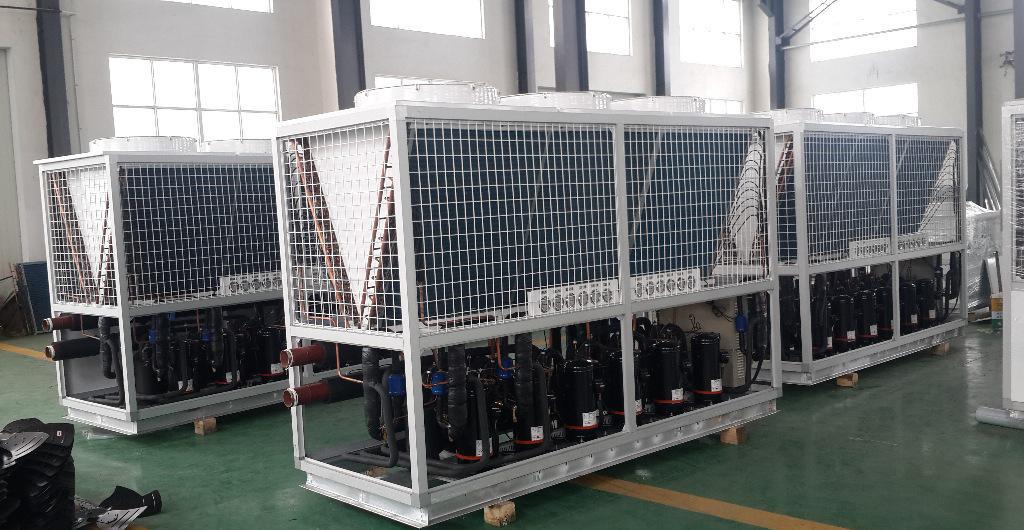

Host installation

The installation position of the main engine is fixed with bolts, and there are shock cushion, cement pier and drainage ditch below the unit. To sum up, the installation position of the host has the following requirements: installation foundation,fixed with bolts,shock absorption measures,and drainage channel. The host installation also considers the distance from the surrounding objects, and the distance is too close will affect the heat exchange. The general requirement is good ventilation and adequate maintenance space. The specification requires that the distance is not less than 3 meters from the roof, not less than 2 meters from the objects before and after, and not less than 1 meter between the units.

The balance pressure of the host leakage check system is generally close to the corresponding saturation pressure at the ambient temperature. After the unit is in place, the leakage inspection should also be conducted step by step. The method is to observe the own pressure gauge on the unit or measure the balance pressure of the system with a composite pressure gauge, which is required to be close to the corresponding saturation pressure at the ambient temperature.

Fan coil installation fan coil

installation method: between the air duct and the room air supply outlet should be added soft connection, both vibration reduction and easy to install. Add 50~200mm soft connection between the air outlet and the air duct and heat preservation. Air duct shall be installed horizontally with diameter or long side size less than or equal to 400mm, spacing shall not be more than 4m; greater than 400mm, not more than 3m. The air duct shall be installed vertically, and the spacing shall not be greater than 4m, and a single straight pipe shall have at least two fixed points.

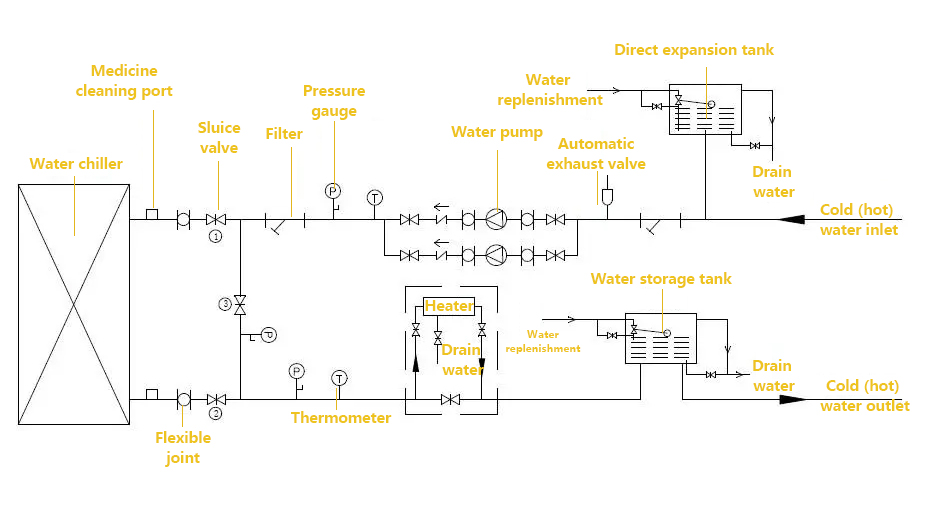

Auxiliary equipment installation

The inlet and outlet of the main engine: install the soft connection, the pressure gauge, the thermometer and the butterfly valve.

Water pump: the installation of the pump is relatively complex, the main purpose is to ensure the normal operation of the pump and facilitate maintenance. Many parts are installed in front and back, forming standard components, including manual stop valve, Y type filter, soft joint, pressure gauge, check valve, etc.

Expansion water tank The expansion water tank is an important device to enable the water system to adapt to the volume expansion caused by the change of water temperature, stabilize the water pressure, and make the water system stable work. It is composed of water supply pipe, expansion pipe, overflow pipe, sewage pipe, and anti-freezing circulation pipe. The micro pressure difference between the expansion tube and the circulation tube is used to form the water microcirculation to achieve the purpose of antifreezing.

Schematic diagram of the air-cooling module water system

Water pipe construction

In order to connect the main engine, fan coil pipe and auxiliary equipment, water pipe construction is necessary. This work mainly includes:lifting, bracket installation, pipe connection, pipe pressure test,pipe cleaning, drainage pipe installationand water testing, pipe insulation and protection.

distribution and communication

The power line specifications of air cooling module cooling and hot water unit are selected according to the requirements of the manual, and an electrical box needs to be specially made to install the AC contactor for auxiliary electric heating and water pump. The power supply of each module is independently controlled to facilitate unit management and maintenance.